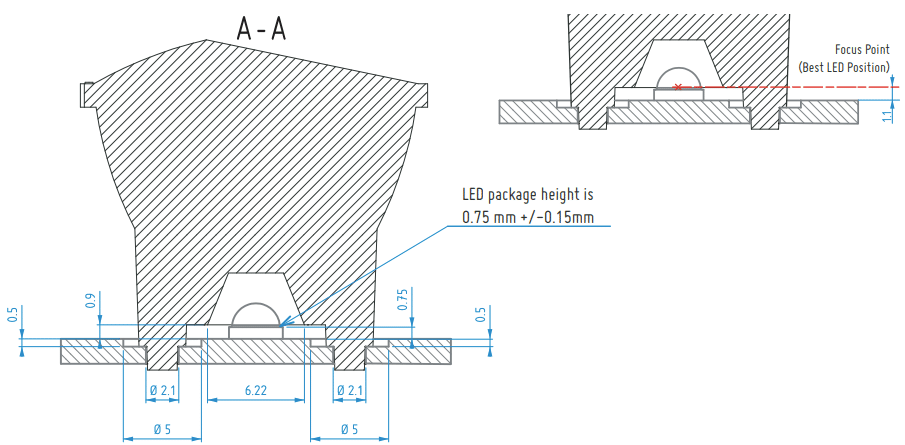

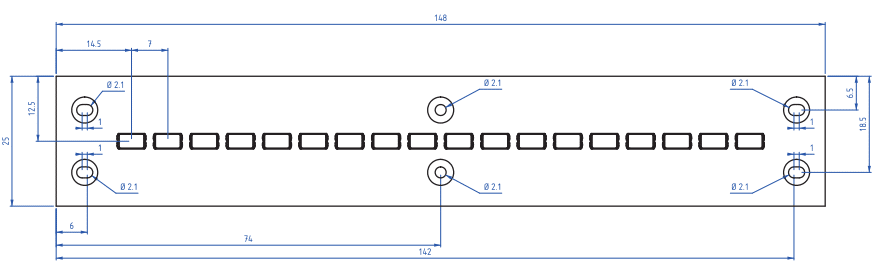

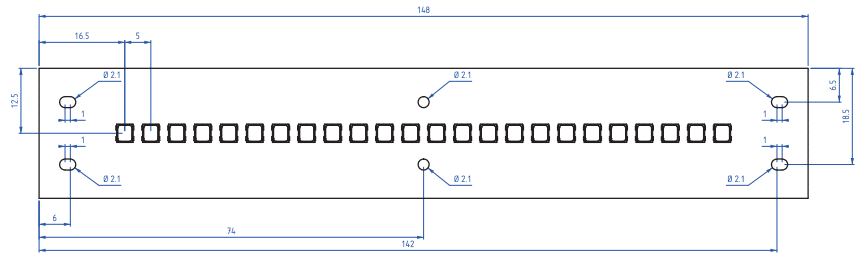

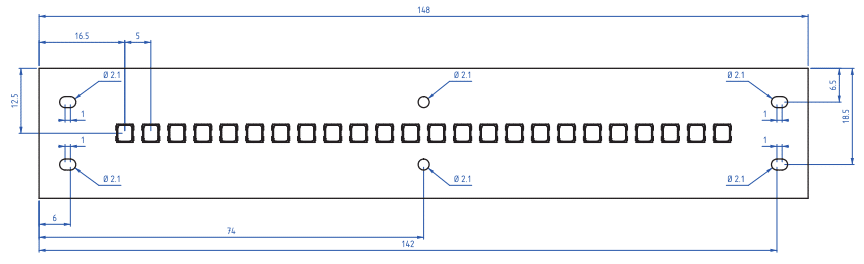

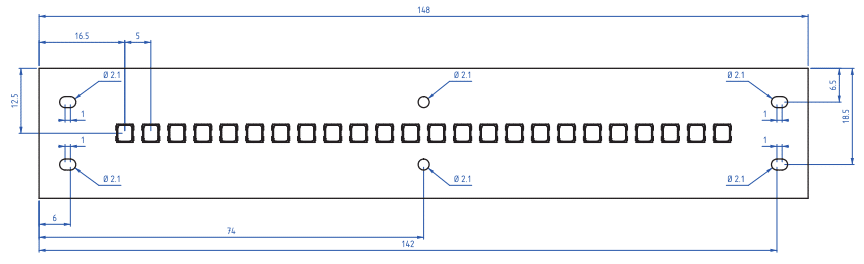

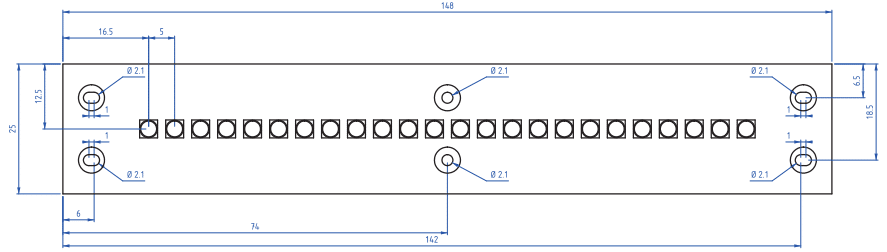

Linear silicone collimators have been designed to be compatible with both high power or mid power LED. Demonstrators have been manufactured using CREE XPE and OSRAM DURIS S5. The two main points to be taken into consideration are the LED package size and the LED thickness related to focus point. A particular attention will have to be taken regarding the focus position of the collimator. Depending on the LED package thickness, a PCB routing might be necessary to ensure a proper alignement of the Light Emitting Surface of the LED with the collimator focal position. A thickness of 1.25mm requires no additional routing. The following schematics describes the recommended PCB configuration for both 0.75mm and 1.25mm LED package thickness :

These collimators are manufactured with Shore 70 silicone. When coupling multiple collimators together, it is recommended to keep a 1 mm to 2 mm gap between collimators to comply with the thermal expansion of the material : 27.5 x 10-5 cm/cm/°C. We recommend to glue the collimator feet to the PCB after assembly using silicone glue. The compatibility between the selected glue and the LED material has to be confirmed by the LED manufacturer to avoid any unwanted chemical interaction. We do not recommend to cut the collimator feet to match the exact LED focus point. Even if manufactured in a soft material, it will not be possible to have an accurate machining of the parts to ensure a proper alignement of the part on the PCB. For information, same PCB design and LED focus point adaptation will apply for both references.

We recommend using :

• 12 to 24 LED per collimator for High power LED.

• 18 to 32 LED per collimator for 5630 or 3030 midpower LED.

Follow our product launches at the rate of maximum one email per month. We will not share your information with any third party, and you can unsubscribe at any time.

Access our past newsletters.

3, rue de la Rolland

01460 MONTRÉAL-LA-CLUSE – FRANCE

Tel. : + 33 (0)4 74 76 12 66